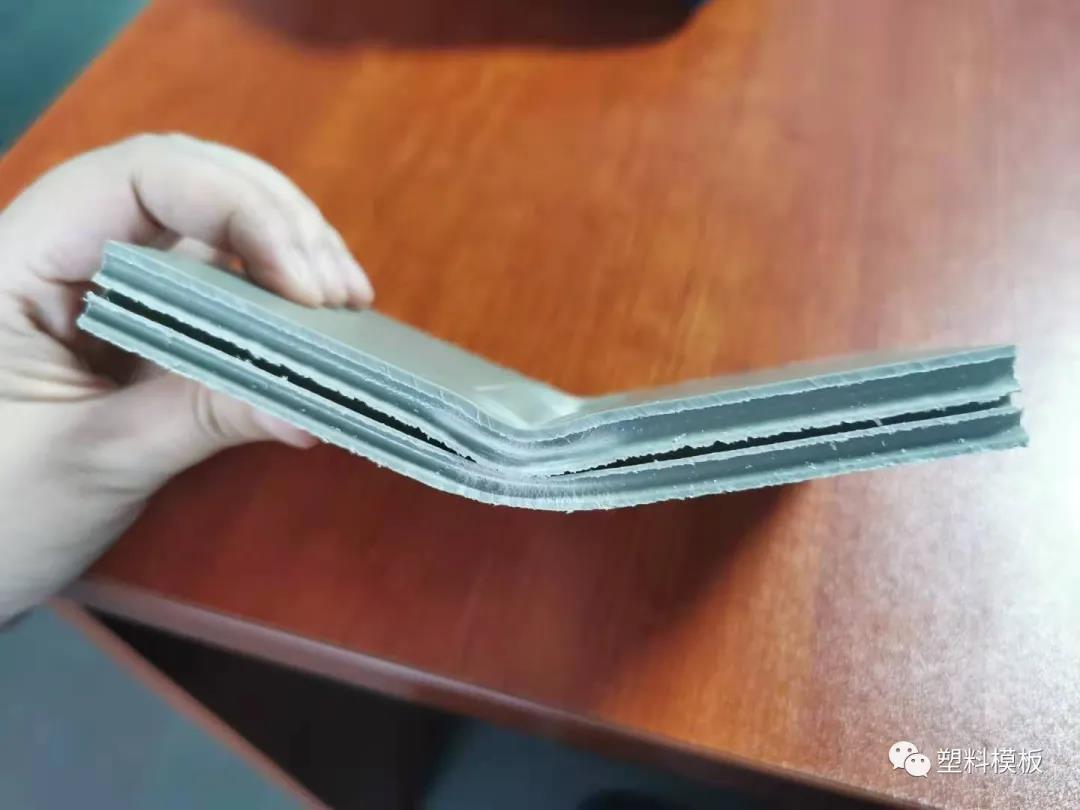

As we all know, plastic formwork is made of plastic, and even the best quality plastic formwork can't avoid the phenomena of softening when exposed to heat and brittleness after precooling. In the process of construction, especially after being used for a period of time, the deformed plastic formwork will affect the quality of the project. Therefore, when the building formwork is deformed, many people will choose to use a new formwork instead, but nothing in this world can be perfect, and there will always be some minor flaws.

Summarized the following main causes of plastic formwork deformation:

1. The spacing between building formwork support and purlin is too large, and the stiffness of building formwork is poor;

2. When assembling small steel forms, the connectors are not set according to regulations, resulting in poor overall performance of the building formwork;

3. The wall building formwork has no opposite bolts, or the spacing between bolts is too large, and the rules of bolts are too small.

4. The wooden building formwork or plywood is used for construction, and the concrete is not poured in time after passing the acceptance test, resulting in long-term exposure to the sun and rain.

5. The low-level of the placed template is not firm and flat, and the poor waterproof measures lead to the settlement of the foundation;

In fact, there are many reasons that lead to the deformation of plastic building formwork, besides the quality of plastic building formwork itself, it is also caused by the wrong way of using and maintaining the building formwork.

After finding the reason, we can prescribe the right medicine according to different situations, and then solve the problem to prevent the deformation of the plastic template.

Solution to deformation of plastic formwork;

1. When assembling small steel moulds, the fittings shall be placed according to regulations, and the spacing and specifications of the purlin and the bolt shall be set according to the design requirements.

2. The support spacing at the bottom of the beam should be able to ensure that it will not deform under the action of concrete weight and construction load. If the bottom of the support is a soil foundation, it should be carefully compacted, a drainage ditch should be set up, and long skids or section steel should be laid to ensure that the support will not sink.

3. When wooden building formwork and plywood building formwork are used for construction, concrete shall be poured in time after acceptance to prevent deformation of wooden building formwork after long-term exposure to rain

4. When designing the building formwork and supporting system, full consideration should be given to its own self-weight, construction load, self-satisfaction of concrete and lateral pressure generated during concrete pouring, so as to ensure that the building formwork and support have sufficient bearing capacity, stiffness and stability.

5. For cast-in-place reinforced concrete beams and slabs with a span of not less than 4m, the building formwork shall be arched according to the design requirements; When there is no specific requirement in the design, the arch height should be 1/1000-3/1000 of the span.

To learn more about hollow plastic template, you can pay attention to WeChat WeChat official account "Plastic Template". Fujian Suxinwang New Energy Co., Ltd. always adheres to the tenet of "quality first, honesty first, win-win cooperation and customer-centered", continuously improves products to meet customer needs, and sincerely welcomes new and old customers to visit and negotiate business! Tel: 0596-3295 888, 139 5014 2388; 400-8339-008,139 2577 5994!