1. What is a hollow plastic template? A: Hollow plastic formwork is a new type of construction material. Hollow plastic formwork adopts modern HDPE and HDPP materials. It is a light weight, non-toxic, non-polluting, waterproof, moisture-proof, and corrosion-resistant construction auxiliary material that can be used for Walls, stairs, bridges, tunnels and water conservancy construction;

2. How many hollow plastic templates are there? Answer: The density of hollow plastic formwork is 0.4g/cubic centimeter, which is only 1/21 of steel. Light weight is more suitable for high-rise building construction. A worker can easily take a 900mm*1800mm formwork with both hands;

3. Can the hollow plastic template be recycled? Answer: Yes, the hollow plastic formwork can be recycled 60 to 100 times. Whether it is the whole board or the waste board, all of it is 100% recycled or replaced with old ones;

4. What is the bearing capacity of hollow plastic formwork? Answer: The hollow plastic template has high strength, strong toughness, impact resistance and strong elasticity. A hollow plastic template can bear the weight of at least three adult men;

5. Can hollow plastic formwork be used with wooden formwork or other boards? Answer: Yes, the hollow plastic formwork can be used with wood formwork or other plates;

6. Do mold release agents need to be used for hollow plastic building templates? Answer: No, the release agent itself is harmful to the human body. The surface of the hollow plastic template is smooth, and it does not absorb cement. It can be detached by tapping the template. The operation is convenient and fast, which effectively speeds up the project and reduces a considerable amount of money. Template cleaning and maintenance fees;

7. What is the degree of cold and heat resistance of the hollow plastic formwork? Answer: The hollow plastic template has a small expansion coefficient, and does not shrink, swell, crack, or deform at a temperature of -10°C to 70°C, and has stable dimensions.

8. How efficient is the construction of hollow plastic formwork? Answer: Under the same workload, the construction efficiency of hollow plastic formwork is 40% higher than that of steel formwork. Compared with bamboo and wood formwork, the construction efficiency can be increased by more than 40%.

9. Is the hollow plastic formwork a "green and environmentally friendly" building material? Answer: Yes, the hollow plastic formwork realizes the production concept of "plastering wood with plastic" and "plastering bamboo with plastic". It does not produce toxic gases to pollute the environment, is recyclable, and does not produce harmful construction waste. Environmental protection and health, harmless to human body;

10. Is the plasticity of the hollow plastic building template strong or not? Answer: The plasticity of the hollow plastic building template is very poor and very strong. It can be sawed, planed, drilled, and nailed. It can be combined with accessories to form any geometric shape, which can meet the needs of various forms of building components in construction;

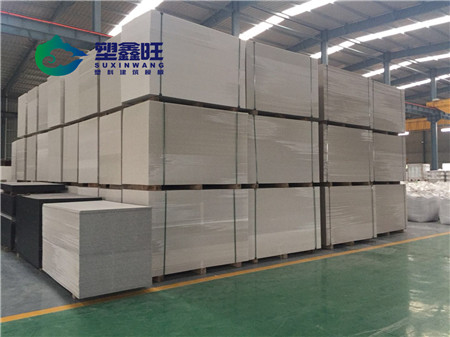

Photo/text: Fujian Plastic Xinwang New Energy Co., Ltd.